Eastman Talks Increasing Demand for Recycled Materials

Holli Alexander, Eastman’s strategic initiative manager of global sustainability, discusses the company’s recycling initiatives.

I recently attended the Plastics Recycling Conference in Nashville, Tenn. Much talk centered on how brand owner commitments to using more recycled material are placing an increasing amount of importance on obtaining recycled feedstock. This prompts an important question: where is this additional material going to come from?

Last year, we saw lots of new announcements from material companies getting involved in the recycled arena. One big player is Eastman, which sees sourcing recycled feedstock as both a “challenge and an opportunity” for the industry.

Holli Alexander, Eastman’s strategic initiative manager of global sustainability.

During the conference, I sat down with Holli Alexander, Eastman’s strategic initiative manager of global sustainability, to talk about how to tackle the supply-demand gap.

Alexander said that being able to apply technologies to start to create solutions for the plastics waste problem has been really exciting for the company.

“And these aren’t new technologies,” she said. “So it’s been the ability to apply what we already know and be able to create a solution is where we started.”

Eastman announced two major recycling initiatives last year. Carbon renewal technology (CRT) is a chemical recycling process that diverts mixed waste plastic from landfills and converts it into molecular components that are then reintroduced in the production of a variety of Eastman products. CRT is now operating at scale. Eastman struck a deal in November 2019 to source feedstock from Circular Polymers, a post-consumer waste reclaimer. The collaboration will divert millions of pounds of discarded carpet fibers from landfills in its first year, according to Mark Costa, Eastman board chair and CEO.

Eastman’s carbon renewal technology is operated in Kingsport, Tenn.

Carbon renewal technology is operated in Kingsport, the company’s largest manufacturing site and world headquarters. Eastman modified the front end of its acetyls and cellulosics production processes to accept waste plastic, reducing the amount of fossil feedstocks required. Carbon renewal technology has a significantly improved carbon footprint compared to the use of fossil feedstocks, according to preliminary lifecycle analysis studies by Eastman scientists.

Eastman’s second recycling project, polyester renewal technology (PRT), is a chemical recycling process specifically for polyester waste, including colored PET and copolyesters, which produces virgin-like materials. The first phase of PRT uses glycolysis to disassemble waste PET into its fundamental building blocks, which are then used to produce new polyesters with high levels of recycled content achieved through certified mass balance allocation. A later phase of PRT using methanol to break down a wide variety of waste polyesters will be fully operational by 2022.

The company is leveraging these recycling technologies for applications in cosmetics, food and beverage packaging and in its full line of resins for shrink films, including its APR-approved Eastman Embrace Encore and Eastman Embrace Float copolyesters.

“A big part of what I’ve been talking about at these events has to do a lot with supply chain and feedstocks because these are the biggest challenges for us,” Alexander said.

“The challenge for us is going to be how do we get the materials? Where we do find them? How do we transform and recreate this concept of what is recyclable? Building new supply chains is complex.”

Chemical Recycling’s Role

While there has been much talk about chemical recycling, there has been just as much confusion to meet it.

“We are living with an existing paradigm that recycling means mechanical recycling. Advanced recycling technologies are still very unknown, but they unlock the potential for materials that were previously ‘unrecyclable’ to now be recycled. With that in mind, how do we start to redefine ‘design for recyclability’ with new options for end-of-life?”

As more brands pledge to use recycled content, Alexander said it’s going to take multiple solutions to come together to create different end-of-life options.

“We’re really excited to see the chemical recycling technologies continue to advance and we’re seeing those as being very complementary to mechanical recycling,” Alexander said.

Related Content

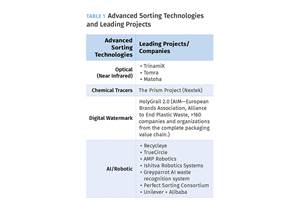

Recycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreRecycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MoreRead Next

What Is the Circular Economy?

In this video from K 2019, hear NOVA Chemicals, TOMRA, Covestro, Rapid Granulator and SABIC each discuss plastics’ role in the circular economy.

Read MoreEastman to Use Reclaimed Polyester Carpet as Feedstock for Chemical Recycling

The reclaimed polyester carpet will be collected and processed by Circular Polymers, transported by railcar, and then upcycled by Eastman to produce new materials with certified recycled content.

Read MoreRecycling & Scrap Reclaim: Machinery Technology Advances as 'Circular Economy' Takes Hold

The circular economy and recycling were the top themes at K 2019, and machine builders responded with new systems to improve equipment performance and material quality.

Read More

.png;maxWidth=300;quality=90)